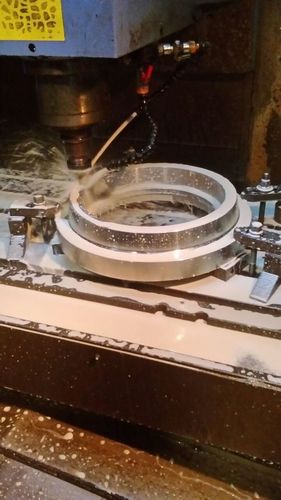

Rotor Balancing Machine

Product Details:

- Material Mild Steel

- Power Electric

- Click to view more

X

Rotor Balancing Machine Price And Quantity

- 1 Unit

Rotor Balancing Machine Product Specifications

- Mild Steel

- Electric

Rotor Balancing Machine Trade Information

- No

Product Description

A rotor balancing machine is a specialized device used to measure and correct any imbalances in rotating components such as rotors, fans, impellers, or shafts. It helps ensure smooth and efficient operation by identifying and eliminating vibrations caused by uneven distribution of mass. Rotor balancing machines employ various techniques, such as dynamic balancing, to achieve optimal balance and improve the performance and lifespan of rotating equipment.

Frequently Asked Questions (FAQ):

Q: What is a rotor balancing machine?

A: A rotor balancing machine is a dedicated machine used to measure and correct imbalances in rotating components. It is designed to detect any uneven distribution of mass within a rotor, fan, impeller, or shaft. By identifying and correcting these imbalances, a rotor balancing machine helps minimize vibrations, reduce stress on the rotating equipment, and enhance its overall performance and reliability.

Q: Why is rotor balancing important?

A: Rotor balancing is important because even small imbalances in rotating components can lead to significant issues, such as increased vibrations, reduced efficiency, and accelerated wear and tear. Unbalanced rotors can cause excessive stress on bearings, increase energy consumption, and compromise the lifespan of the equipment. By balancing rotors, the machine's performance, reliability, and service life can be improved.

Q: How does a rotor balancing machine work?

A: Rotor balancing machines work by measuring the vibrations and identifying the imbalances in a rotating component. The component is mounted on the machine, and it is then rotated at high speeds. Sensors in the machine measure the vibrations caused by the imbalances. Based on the measurements, the machine determines the corrective actions needed to balance the rotor. This may involve adding or removing weight from specific locations on the rotor until the vibrations are minimized, and the rotor achieves optimal balance.

Q: What is dynamic balancing?

A: Dynamic balancing is a technique used in rotor balancing machines to correct imbalances in rotating components. It involves the measurement of vibrations at different points of the rotor while it is rotating. The machine analyzes the vibration data and determines the magnitude and location of the imbalance. To achieve balance, weights are added or removed at specific positions on the rotor until the vibrations are reduced to an acceptable level.

Q: What are the benefits of using a rotor balancing machine?

A: Using a rotor balancing machine offers several benefits. It helps reduce vibrations, which in turn minimizes stress on the equipment and extends its lifespan. Balanced rotors improve the efficiency of rotating machinery, resulting in energy savings. By eliminating imbalances, rotor balancing machines enhance the overall performance and reliability of the equipment, leading to smoother operation and reduced maintenance requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email